The energy audit is an effective tool to explore the relationship between the energy consumed and production.

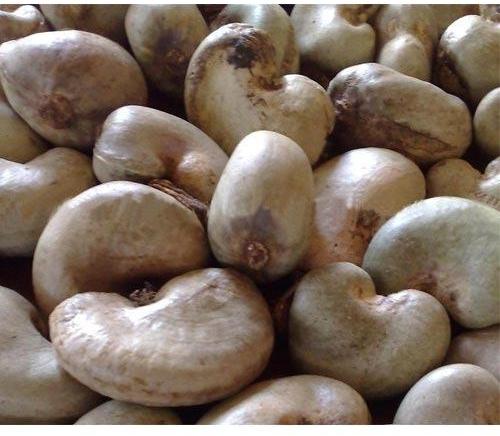

The wide variations in energy intensity of these cashew mills reveal the scope for energy conservation to be in the order of 30 to 48%. A wide disparity in energy consumption to produce the same quantity of similar products in cashew processing was observed. The cutting and shelling operation performed in the mill generates huge quantity of the cashew nut shell that is, about 67% of total weight of raw cashew nut seeds. The steaming of raw cashew nut seed prior to cutting and shelling operation is widely adopted method in small-scale cashew nut processing mills. The most energy and time intensive unit operations in cashew processing are drying of raw seed in open sun, steaming of raw nut and kernel drying with electrical energy. The cashew mill in India employed different unit operations/methodology for processing and depending on variety of raw material, location, technological mechanization, and availability of secured energy supply. India processed about 11,38,000 tones of raw cashew nut seeds through 3650 cashew processing mills scattered in many states of country. Total area in India under cashew cultivation is about 8,68,000 ha with annual production of 6,65,000 tons giving average productivity 860 kg per hectare. India is the largest producer and processor of cashews ( Anacardium occidentale L.) in the world. Its suitability as a supplementary fuel for thermal application TheĪvailability and fuel analysis of the cashew shell as a fuel revealed The thermogravimetricĪnalysis revealed that 85% weight of cashew nut shell has beenĭegraded at 500 ∘C and in 13 minutes. The average higher calorific value of the cashew nut Total weight of cashew seed, which can be utilized as fuel for thermalĮnergy supply. In small-scale cashew processing industries was found to be 67.5% of Process with average energy consumption accounted to be 2969.7 MJ perġ000 kg of raw cashew seed. The small-scale cashew processing industries followed steam-cooking The thermogravimetric analysis of theĬashew shell was carried out using TG-FTIR withġ0 ∘C/minute heating rate. The calorific value of the cashew shell was carried out usingīomb calorimeter (ASTME 711). Of cashew shell waste was carried out using ASTMD 73–75 The Main operations in the Cashew Nut Processing are :The energy and mass flow of the steam cooking operation of three readilyĭefined small-scale cashew processing industries was studied toĮstimate the availability of cashew nut shell.

We execute customized turnkey projects for cashew nut process plants of any capacity in both semi automatic and Automatic We also offer complete project consultancy.

We understand client's requirements in terms of Production Capacity, Unit Area and Investment allocation, based on that we design a customized plant.

CASHEW SHELL INSTALL

We offer our services to install processing machinery and train your employees skills in Cashew processing & machinery maintenance to produce world class Cashew Kernel. We also arrange experienced team of manpower for our clients as we can say "Skilled Manpower is the Heart of Cashew Industry". We deliver fully automatic turnkey Projects with total quality Management through our high skilled Engineers. Please note that we are well equipped to provide you Cashew Processing Plant on Turnkey basis. We have been exported turnkey plant in African Countries like Mozambique, Gambia, Ghana, Ivory Coast, Tanzania, Zambia, Kenya, Nigeria, Benin and other countries like Dubai, Turkey, Egypt, Jordan, Algeria, Lebanon etc. We are a world leader in cashew processing machinery as a turnkey project in India and Overseas countries, with the innovation and the technology Upgradation of Cashew Processing Machinery. RAMI INTERNATIONAL is the leading manufacturer and Exporter of Turn Key Cashew Processing Plant.

0 kommentar(er)

0 kommentar(er)